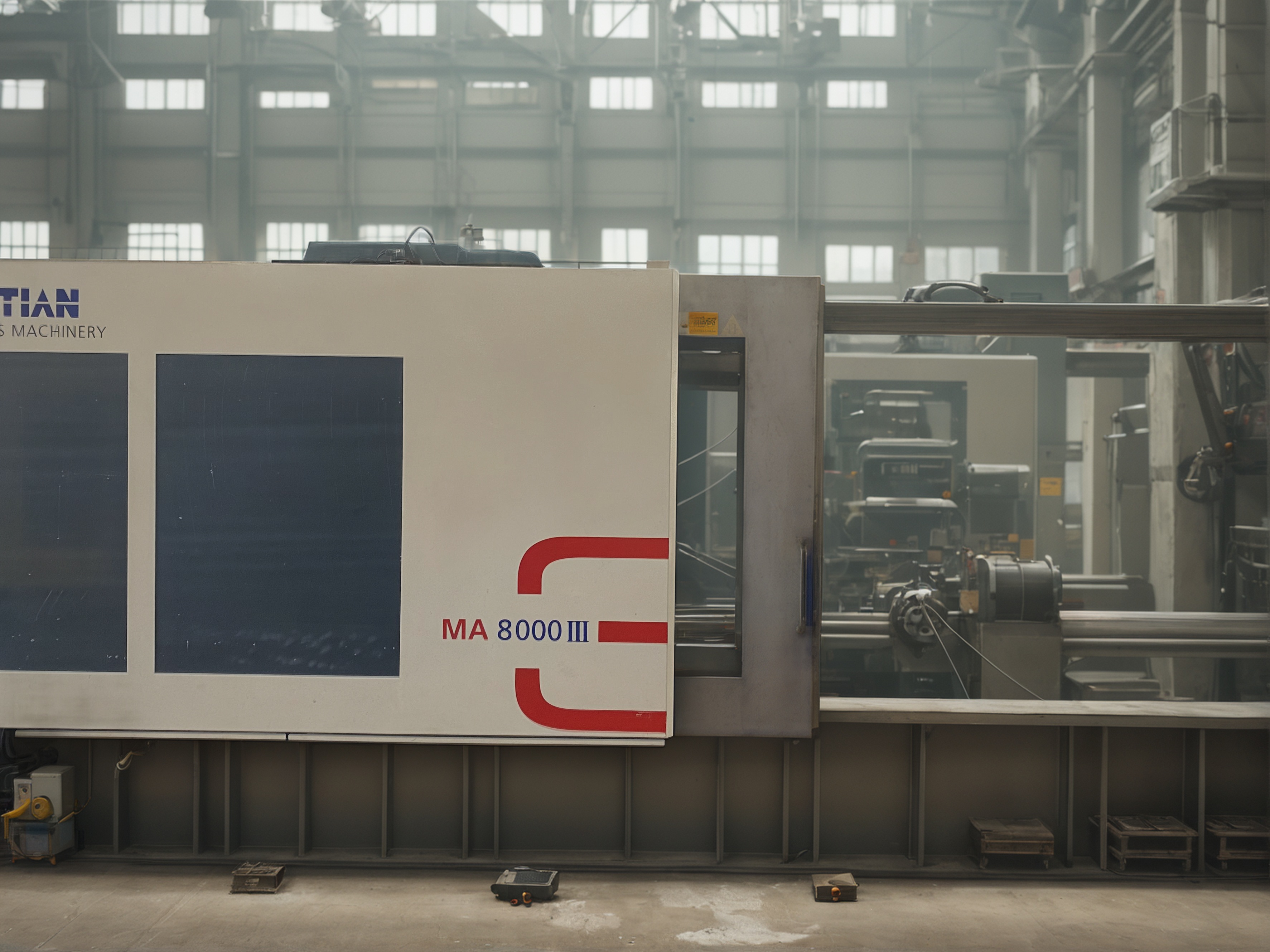

In the competitive landscape of modern manufacturing, the selection of production equipment is a critical decision that directly impacts efficiency, quality, and profitability. While many operations rely on a standard conventional machine, the push for greater performance and sustainability has led to the evolution of these essential tools. The Haitian MA2000III/750 Injection Molding Machine stands as a prime example of this evolution, representing a pinnacle of engineering that combines robust, reliable mechanics with advanced, energy-saving technology. This machine is not merely a piece of equipment; it is a comprehensive solution designed to meet the rigorous demands of today's plastic production industry, offering unparalleled precision, operational efficiency, and long-term value for businesses across diverse sectors.

At the core of the MA2000III/750's exceptional performance is its highly sophisticated servo-hydraulic system. This innovative technology marks a significant departure from older, less efficient hydraulic systems by intelligently managing power consumption. The servo motor adjusts its output based on the real-time needs of the molding cycle, delivering power only when required. This results in staggering energy savings of up to 80% compared to traditional hydraulic machines, a benefit that translates directly into lower operational costs and a significantly reduced carbon footprint. Beyond its economic and environmental advantages, this system provides superior control and repeatability. The precision of the servo-hydraulics ensures that every movement, from mold clamping to injection and ejection, is executed with remarkable accuracy, minimizing material waste and ensuring consistent, high-quality part production, cycle after cycle. With a formidable clamping force of 2000 kN (200 tons) and a generous shot weight capacity of 750 grams, the MA2000III/750 is built to handle a vast array of production tasks, from small, intricate components to larger, more substantial molded parts, making it a truly versatile workhorse.

User experience and operational simplicity are central to the design philosophy of the MA2000III/750. The machine features a large, high-resolution control panel with an intuitive and user-friendly interface. This advanced control system simplifies the programming of complex molding processes, allowing operators to set parameters, monitor production in real-time, and diagnose issues with ease. The clear graphical display and responsive controls reduce the learning curve for new operators and minimize the potential for human error, leading to increased uptime and smoother production flows. The physical construction of the machine itself reflects a commitment to durability and intelligent design. Built with high-quality materials and a robust architecture, the MA2000III/750 is engineered for longevity and reliable performance even in the most demanding, 24/7 production environments. Furthermore, its thoughtfully designed compact footprint optimizes the use of valuable factory floor space, allowing for efficient plant layouts without compromising on power or capacity.

The versatility of the Haitian MA2000III/750 makes it a strategic asset for a wide spectrum of industries. In the automotive sector, it is capable of producing everything from durable interior trim components and complex dashboard elements to under-the-hood parts that must withstand extreme conditions. For the ever-advancing electronics industry, the machine delivers the precision required for manufacturing intricate casings for smartphones, laptops, and other consumer devices. In the consumer goods market, its efficiency and speed are ideal for mass-producing items like containers, toys, and household appliances. Moreover, its high degree of control and cleanliness makes it perfectly suited for the medical and healthcare industry, where it can be used to create sterile device components and high-quality packaging. This ability to adapt to various materials and mold complexities distinguishes it from a typical conventional machine, offering businesses the flexibility to pivot to new products and markets.

Investing in the Haitian MA2000III/750 is a strategic decision that pays dividends long into the future. The substantial energy savings delivered by the servo-hydraulic system provide a clear and measurable return on investment through reduced utility expenses. The machine’s focus on precision and process optimization minimizes material waste and lowers scrap rates, further enhancing profitability. Its durable construction and minimal maintenance requirements contribute to a lower total cost of ownership, ensuring that it remains a productive asset for many years. Backed by the reputation of Haitian Plastics Machinery and the dedicated support network of partners like Geerpower Industrial Co., Ltd., customers can be confident in receiving responsive technical assistance and comprehensive service solutions. This commitment to customer success ensures that the machine operates at peak performance, maximizing productivity and extending its operational life.

In conclusion, the Haitian MA2000III/750 Injection Molding Machine transcends the expectations of a conventional machine. It is a forward-thinking investment in efficiency, quality, and sustainability. By integrating a powerful and precise servo-hydraulic system, a user-centric control interface, and a robust, space-saving design, it provides manufacturers with the tools they need to excel in a competitive global market. Whether for automotive, electronics, consumer goods, or healthcare applications, this machine offers the power, precision, and reliability required to elevate production capabilities, drive down costs, and achieve new levels of manufacturing excellence. It is more than just a machine; it is a catalyst for industrial progress and a cornerstone for a successful production future.

Description

Additional Information

Privacy Policy

People who viewed this also viewed

Conventional Machine Excellence: MA 1600 III Insights

1. Introduction to Conventional Machine

2. MA 1600 III Injection Molding Innovation

3. Design Excellence and Durability

4. Advanced Technology Integration

5. Optimized User Experience

6. Operational Efficiency Boost

7. Global Support Network

8. Conclusion: Partnering for Success

Conventional Machine: Revolutionizing Plastic Production

1. Introduction to Conventional Machine

2. Structural Integrity and Clamping

3. Injection Unit Mechanism

4. Hydraulic Power System

5. Precision Control Panel

6. Versatility Across Industries

7. Conclusion: Excellence in Manufacturing