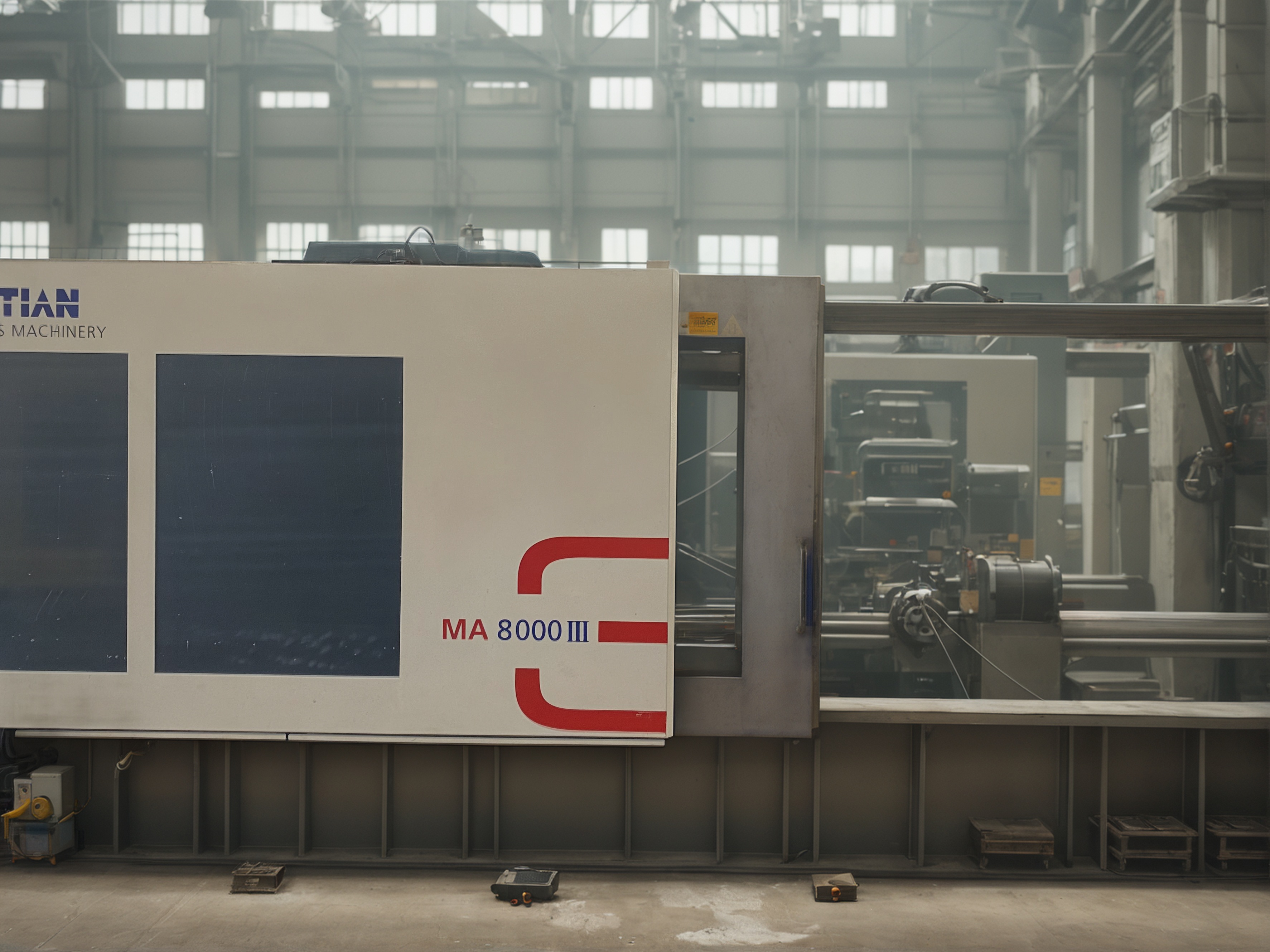

In the dynamic world of industrial manufacturing, where precision, efficiency, and reliability are the pillars of success, the choice of machinery is paramount. For businesses aiming to achieve high-volume production without compromising on quality, the Conventional Machine stands as a time-tested and powerful solution. This cornerstone of modern production, particularly within the demanding field of plastic injection molding, represents the perfect amalgamation of robust engineering, operational control, and enduring performance. It is a testament to the principle that proven technology, when refined and perfected, provides an unparalleled foundation for consistent and profitable manufacturing, delivering the power and precision needed to transform raw materials into flawless finished products on a massive scale.

At the very core of this machine's capability is its formidable physical construction. Built upon a high-grade, heavy-duty frame, it is designed to withstand the immense forces and continuous cycles of a demanding industrial environment. The centerpiece of this structural integrity is the expansive clamping unit, featuring robust platen structures that guarantee unparalleled rigidity and minimize any potential for deflection during the high-pressure injection process. This stability is further enhanced by sleek, chrome-plated tie bars that not only contribute to the machine's longevity but also ensure the smooth, precise alignment and movement of the mold halves. This meticulous engineering of the clamping system is fundamental, as it directly translates to immaculate molding precision, consistent part weight, and the elimination of defects like flash, ensuring every product meets the most stringent quality standards.

Equally impressive is the meticulously designed injection unit, the heart of the machine where raw plastic pellets are transformed into a molten state ready for molding. The process begins at the high-capacity hopper, prominently positioned for easy loading and designed to ensure a steady, uninterrupted flow of material, which is critical for long production runs. From the hopper, the material is fed into a barrel containing a meticulously designed screw mechanism. Here, a combination of friction and state-of-the-art thermal regulation systems work in concert to melt the plastic consistently and homogenously. This precise control over temperature is crucial, safeguarding the integrity of the polymer and ensuring that each shot of molten plastic has the optimal viscosity and flow characteristics for perfectly filling the mold cavity.

Driving the immense power of this machinery is a sophisticated and powerful hydraulic system. This system is the workhorse responsible for generating the massive force required to securely clamp the mold shut and to inject the molten plastic at high pressure. Engineered for optimal energy efficiency and seamless operational performance, modern hydraulic systems integrate cutting-edge components that reduce power consumption while improving cycle times. Insulated piping and logically placed connectors not only enhance the machine’s longevity by protecting its vital components but also simplify maintenance procedures. The sheer reliability of the hydraulic system ensures that the machine can operate continuously, delivering consistent force cycle after cycle, which is essential for maintaining uniformity across vast batches of products.

Mastery over this power is granted to the operator through an advanced, yet intuitive, control panel. This centralized interface is the brain of the operation, allowing for the precise fine-tuning of every critical parameter in the molding process. Operators can program and adjust injection speeds, holding pressures, cooling times, and temperatures with exceptional accuracy. This level of granular control is what enables the machine to adapt to a vast array of material requirements and complex mold geometries. Furthermore, integrated safety features, including prominent emergency shut-off capabilities and a visible alert system that provides real-time status updates through vibrant signal lighting, ensure a safe and transparent operational environment. This system alerts operators to completed cycles, low material levels, or any potential workflow disruptions, maximizing uptime and maintaining quality control.

The true value of this injection molding machine lies in its remarkable versatility. It is not designed for a single purpose but is engineered to be a dynamic and flexible asset for a wide range of industries. Whether it’s producing intricate components for the automotive sector, sterile devices for the medical field, or high-volume consumer goods, this machine can be equipped with an endless variety of molds. Its robust design allows it to handle everything from small, delicate parts to larger, more substantial products with equal precision. The thoughtful placement of accessible doors and panels ensures that maintenance and mold changes are straightforward and efficient, minimizing downtime and keeping production lines running smoothly. This blend of power and adaptability makes the Conventional Machine a strategic investment for any manufacturer looking to scale their operations.

In conclusion, this state-of-the-art injection molding machine embodies the pinnacle of industrial engineering, merging raw power with refined precision. Its durable construction, advanced hydraulic and thermal systems, and user-centric controls all combine to create a manufacturing powerhouse. It represents a commitment to quality, efficiency, and longevity, offering businesses the reliability needed to compete in a fast-paced market. By providing a stable and highly capable platform for a wide spectrum of plastic processing applications, this machine is not just a piece of equipment; it is a catalyst for innovation and a guarantee of production excellence, ready to elevate any manufacturing facility to unprecedented heights of productivity and success.

Description

Additional Information

Privacy Policy

People who viewed this also viewed

Conventional Machine Excellence: MA 1600 III Insights

1. Introduction to Conventional Machine

2. MA 1600 III Injection Molding Innovation

3. Design Excellence and Durability

4. Advanced Technology Integration

5. Optimized User Experience

6. Operational Efficiency Boost

7. Global Support Network

8. Conclusion: Partnering for Success

Conventional Machine: Revolutionizing Plastic Production

1. Introduction to Conventional Machine

2. Structural Integrity and Clamping

3. Injection Unit Mechanism

4. Hydraulic Power System

5. Precision Control Panel

6. Versatility Across Industries

7. Conclusion: Excellence in Manufacturing