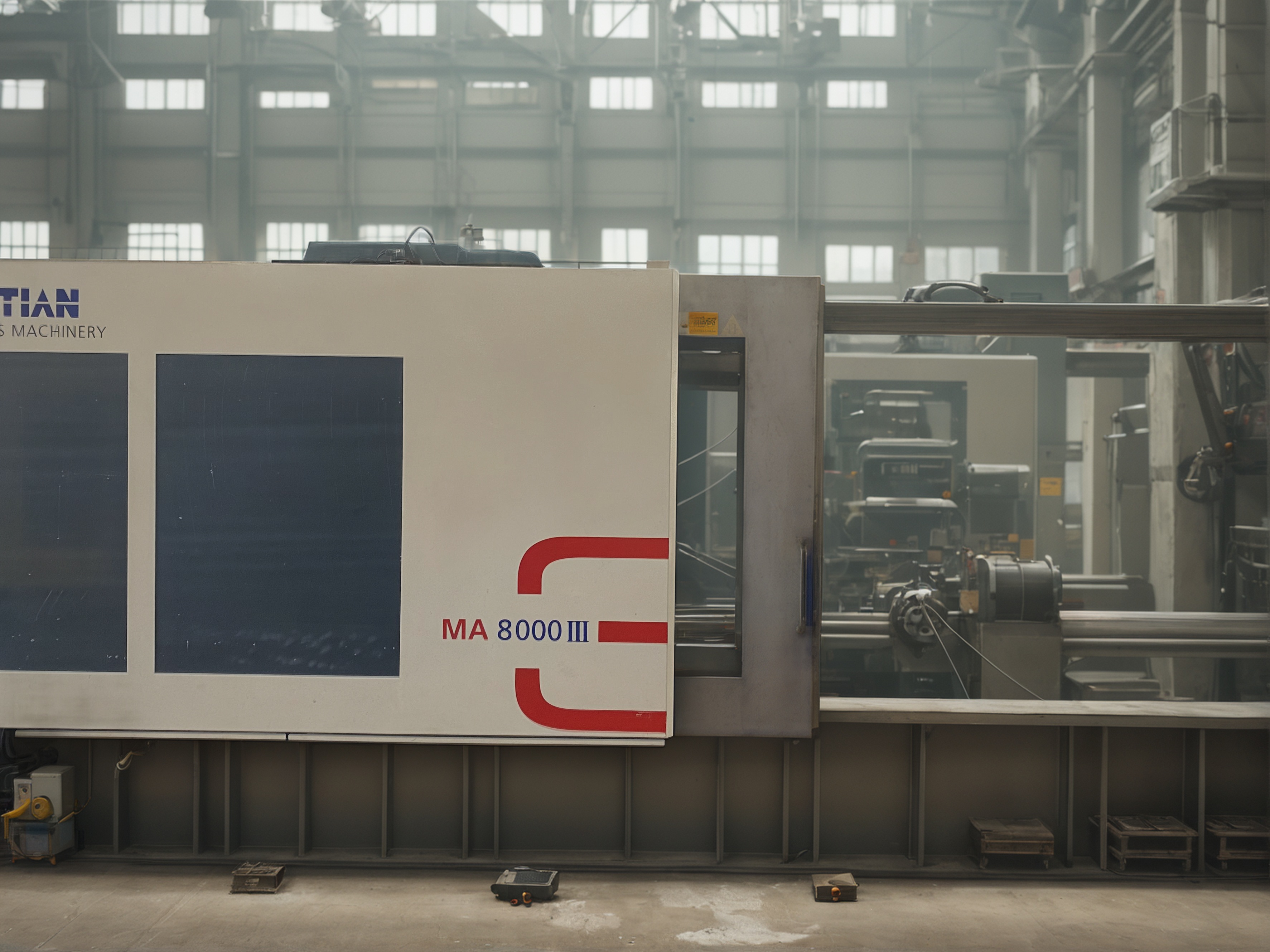

In the highly competitive world of plastic manufacturing, the choice of machinery is a critical determinant of success, influencing everything from production efficiency and product quality to operational costs. While specialized equipment has its place, the backbone of many successful operations remains the robust and reliable Conventional Machine. Geerpower Industrial Co., Ltd. elevates this essential category with the introduction of the MA 1600 III injection molding machine, a testament to the perfect synergy between proven engineering principles and modern technological advancements. This machine is not just a piece of equipment; it is a comprehensive solution designed to empower manufacturers, drive industrial development, and deliver cost-effective, high-quality results for a multitude of sectors.

The MA 1600 III, also known as the MA1600III 570B3, is the culmination of Geerpower's unwavering commitment to perfection. This philosophy permeates every stage of the machine's life cycle, from initial research and development through meticulous design, precision production, and rigorous manufacturing processes. The result is a machine built for unparalleled performance and enduring reliability. At its core, the MA 1600 III boasts a formidable clamping force capacity of 160 tons, providing the stability and strength necessary to ensure maximum mold integrity even during high-volume, continuous production runs. This robust clamping system is crucial for producing intricate and dimensionally accurate plastic parts, minimizing defects and waste while maximizing output. Its durable construction is engineered to withstand the demanding conditions of modern industrial environments, promising a long service life and a significant return on investment.

Beyond its powerful foundation, the MA 1600 III is equipped with sophisticated technology designed to optimize every aspect of the molding process. The machine features a high-efficiency screw design that ensures optimal material plasticization, handling a wide range of polymers with consistent and precise heat management. This is seamlessly integrated with a state-of-the-art hydraulic system that provides smooth, rapid, and exceptionally energy-efficient transitions. This focus on energy efficiency is a key advantage, helping businesses reduce their operational costs and environmental footprint without sacrificing production quality. The true genius of this Conventional Machine lies in its ability to blend raw power with refined control, offering a stable and predictable platform that consistently delivers top-tier results. This blend of power and precision is what enables businesses to meet the stringent quality standards of today's market.

User experience and operational control are central to the design of the MA 1600 III. Geerpower has engineered an advanced, user-friendly control panel with an intuitive interface that simplifies machine operation. This system provides operators with real-time monitoring of all critical process parameters, allowing for precise adjustments and on-the-fly customization to optimize performance for different molds and materials. The clear and logical layout reduces the learning curve for new operators and minimizes the potential for human error. To further enhance oversight, a spacious viewing window is incorporated into the design, allowing operators to safely and effortlessly observe the molding process. This commitment to usability is complemented by strategically placed safety markings and features, ensuring full compliance with international safety standards and protecting the well-being of personnel on the factory floor.

Efficiency in a manufacturing setting is often measured by uptime and throughput. The MA 1600 III is engineered to excel in both areas. A high-capacity hopper ensures a continuous and seamless feed of raw materials into the system, preventing interruptions and maintaining a steady production rhythm. This feature, combined with the machine's overall durable construction and strategic configuration, drastically reduces downtime for material refills and maintenance. By minimizing these non-productive periods, enterprises can significantly boost their overall operational efficiency and meet even the most demanding high-volume output targets. The machine’s sleek white and grey finish not only gives it a modern aesthetic that fits well in contemporary manufacturing facilities but also reflects the clean, organized, and efficient operational philosophy it embodies.

Geerpower Industrial Co., Ltd. understands that a world-class machine is only part of the equation for long-term success. The company backs the MA 1600 III with an extensive global service network, providing clients with access to timely, professional technical support and comprehensive after-sales service. This dedicated support system is staffed by experts with deep industry insights and technological expertise, ready to tackle any production challenges that may arise. This partnership approach ensures that clients can maximize the performance and longevity of their investment, fostering sustainable development and continuous innovation. By choosing the MA 1600 III, businesses are not just acquiring a superior Conventional Machine; they are gaining a reliable partner committed to their growth and success. This machine empowers businesses worldwide to push their production capabilities to new heights, creating a more streamlined, efficient, and profitable future in plastic manufacturing.

Description

Additional Information

Privacy Policy

People who viewed this also viewed

Conventional Machine Excellence: MA 1600 III Insights

1. Introduction to Conventional Machine

2. MA 1600 III Injection Molding Innovation

3. Design Excellence and Durability

4. Advanced Technology Integration

5. Optimized User Experience

6. Operational Efficiency Boost

7. Global Support Network

8. Conclusion: Partnering for Success

Conventional Machine: Revolutionizing Plastic Production

1. Introduction to Conventional Machine

2. Structural Integrity and Clamping

3. Injection Unit Mechanism

4. Hydraulic Power System

5. Precision Control Panel

6. Versatility Across Industries

7. Conclusion: Excellence in Manufacturing