In the ever-evolving landscape of modern manufacturing, the role of the Conventional Machine remains fundamentally indispensable. These titans of industry form the bedrock of production across countless sectors, from automotive components to everyday consumer goods. While often perceived as traditional, today's conventional machinery represents a sophisticated fusion of time-tested mechanical robustness and cutting-edge technological innovation. They are not relics of a bygone era but are powerful, refined workhorses engineered for precision, durability, and high-volume output. A prime example of this evolution can be seen in the realm of injection molding, where these machines continue to set the standard for quality and efficiency, proving that foundational engineering principles, when enhanced with modern technology, create an unbeatable combination for success.

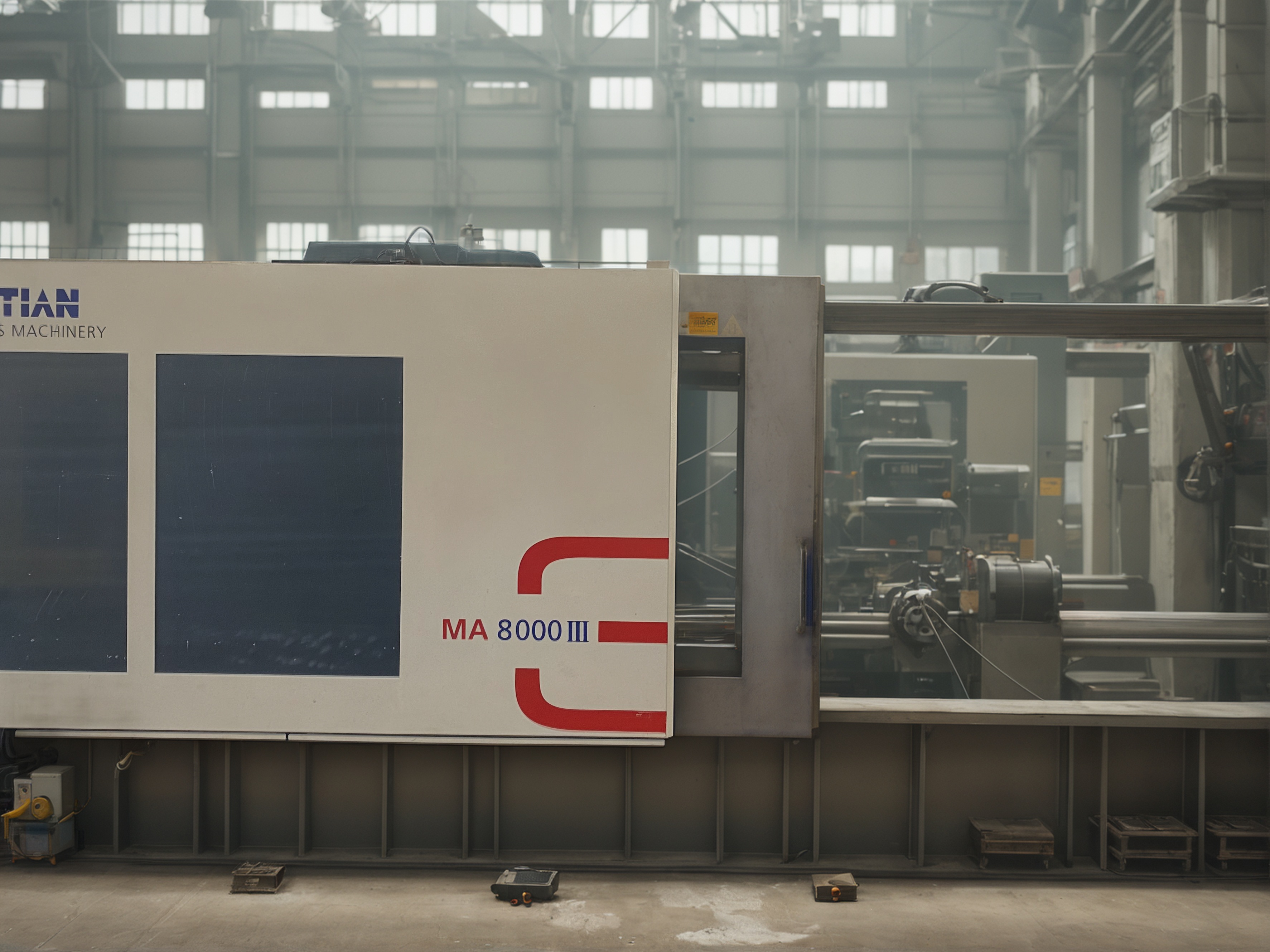

At the very core of any high-quality conventional machine is its construction and foundational design. The emphasis is on a robust framework and a stable chassis, meticulously engineered to withstand the rigorous demands of continuous industrial operation. This architectural marvel, as seen in advanced models like the Geerpower 8400-3, promises exceptional durability and minimizes vibrations, which is crucial for maintaining precision over long production runs. The clamping unit is a testament to this principle of raw power meeting fine control. Machines like the Haitian MA 30000 II/1700 boast an extraordinary clamping force, ensuring that molds are held together with immense pressure. This capability is essential for producing intricate plastic components with flawless surface finishes, tight tolerances, and absolute structural integrity. This blend of a strong, durable chassis with a powerful and precise clamping system is the first pillar upon which the reputation of a reliable manufacturing solution is built.

Beyond the structural frame, the heart of production lies within the injection unit. This critical system is responsible for melting, mixing, and injecting the raw material into the mold with unparalleled consistency. Modern machines are equipped with high-performance injection units that feature powerful screw and barrel designs, pushing the boundaries of productivity by significantly reducing cycle times. Superior control over injection speed and pressure is paramount, empowering manufacturers to tackle complex designs and challenging materials with exceptional accuracy. This level of precision not only enhances the quality of the final product but also contributes significantly to operational efficiency by reducing material waste. By optimizing the injection process, these machines promote sustainability and cost-effectiveness, delivering a tangible return on investment. The integration of advanced servo motor technology further refines this process, delivering superior drive performance with the speed and reliability that modern production lines demand.

Bridging the gap between mechanical strength and operational intelligence is the advanced control system. The modern Conventional Machine has moved far beyond simple analog controls, now featuring intuitive, user-friendly digital interfaces. These command centers, prominently displayed for easy access, provide operators with seamless navigation and real-time data acquisition. This allows for the constant monitoring and on-the-fly adjustment of all critical production parameters, ensuring maximum efficiency and adaptability for diverse manufacturing needs. Whether it's the comprehensive digital control system of the Geerpower 8400-3 or the intuitive interface on the Haitian MA10000III, these systems are gateways to a customizable and responsive manufacturing experience. They empower operators to maintain stringent control over the entire molding process, ensuring every component is produced with unparalleled precision and repeatability, truly embodying the principles of smart manufacturing.

Finally, the long-term value of a Conventional Machine is cemented by its features designed for longevity, safety, and support. Sustained high-performance operation generates significant heat, making an efficient cooling system indispensable. These integrated systems work to maintain optimal operational temperatures, protecting critical components and prolonging the lifespan of the machine while ensuring peak performance. Safety is also at the forefront, with state-of-the-art measures like high-visibility warning indicators and accessible emergency controls that prioritize operator protection and machine integrity. Furthermore, leading manufacturers understand that the purchase of a machine is the beginning of a partnership. Access to a global support network for timely and professional technical assistance is a critical component of the offering, ensuring businesses can maintain seamless production and effectively address any challenges that may arise. This holistic approach to reliability, safety, and support ensures that these machines are not just equipment, but a comprehensive and enduring manufacturing solution, poised to elevate the capabilities of any industrial operation to unprecedented heights.

Description

Additional Information

Privacy Policy

People who viewed this also viewed

Conventional Machine Excellence: MA 1600 III Insights

1. Introduction to Conventional Machine

2. MA 1600 III Injection Molding Innovation

3. Design Excellence and Durability

4. Advanced Technology Integration

5. Optimized User Experience

6. Operational Efficiency Boost

7. Global Support Network

8. Conclusion: Partnering for Success

Conventional Machine: Revolutionizing Plastic Production

1. Introduction to Conventional Machine

2. Structural Integrity and Clamping

3. Injection Unit Mechanism

4. Hydraulic Power System

5. Precision Control Panel

6. Versatility Across Industries

7. Conclusion: Excellence in Manufacturing