In the world of modern manufacturing, the role of a robust and reliable Conventional Machine is absolutely indispensable. These workhorses of the industry form the backbone of production lines across countless sectors, providing the power, precision, and consistency required to transform raw materials into high-quality finished goods. While technology continuously evolves, the fundamental principles of a great conventional machine—durability, efficiency, and unwavering performance—remain the key to industrial success. Today, leading manufacturers are pushing the boundaries of what these machines can achieve, integrating advanced technology with time-tested engineering to deliver unparalleled value. Two outstanding examples of this evolution are the Geerpower 1000T3 and the Haitian Mars Series MA2500 III SE, both of which set new standards in the field of injection molding.

The Geerpower 1000T3 Injection Molding Machine stands as a testament to precision engineering and sophisticated design. It is a powerful representation of how a modern Conventional Machine can merge high performance with operational elegance. At its core, the 1000T3 features a high-performance injection system meticulously designed for unmatched accuracy and consistency. This level of precision is crucial for industries where even the slightest deviation can impact product integrity. The machine's wide-bodied structure and sturdy base are not merely aesthetic choices; they are engineered to ensure maximum stability during high-speed operations. This design minimizes vibrations, which in turn enhances the accuracy of each mold and extends the lifespan of the equipment. With an impressive 1000-ton capability, as indicated by its '1000T3' branding, this machine is built for large-scale production, empowering businesses to meet high-volume demands without sacrificing quality. Geerpower also places a strong emphasis on sustainability, engineering the 1000T3 to optimize energy consumption. This focus on efficiency reduces operational costs and aligns with the growing global demand for environmentally-friendly manufacturing practices. The user experience is further enhanced by an intuitive control interface and a comprehensive support network, ensuring that operators can maximize productivity while minimizing downtime.

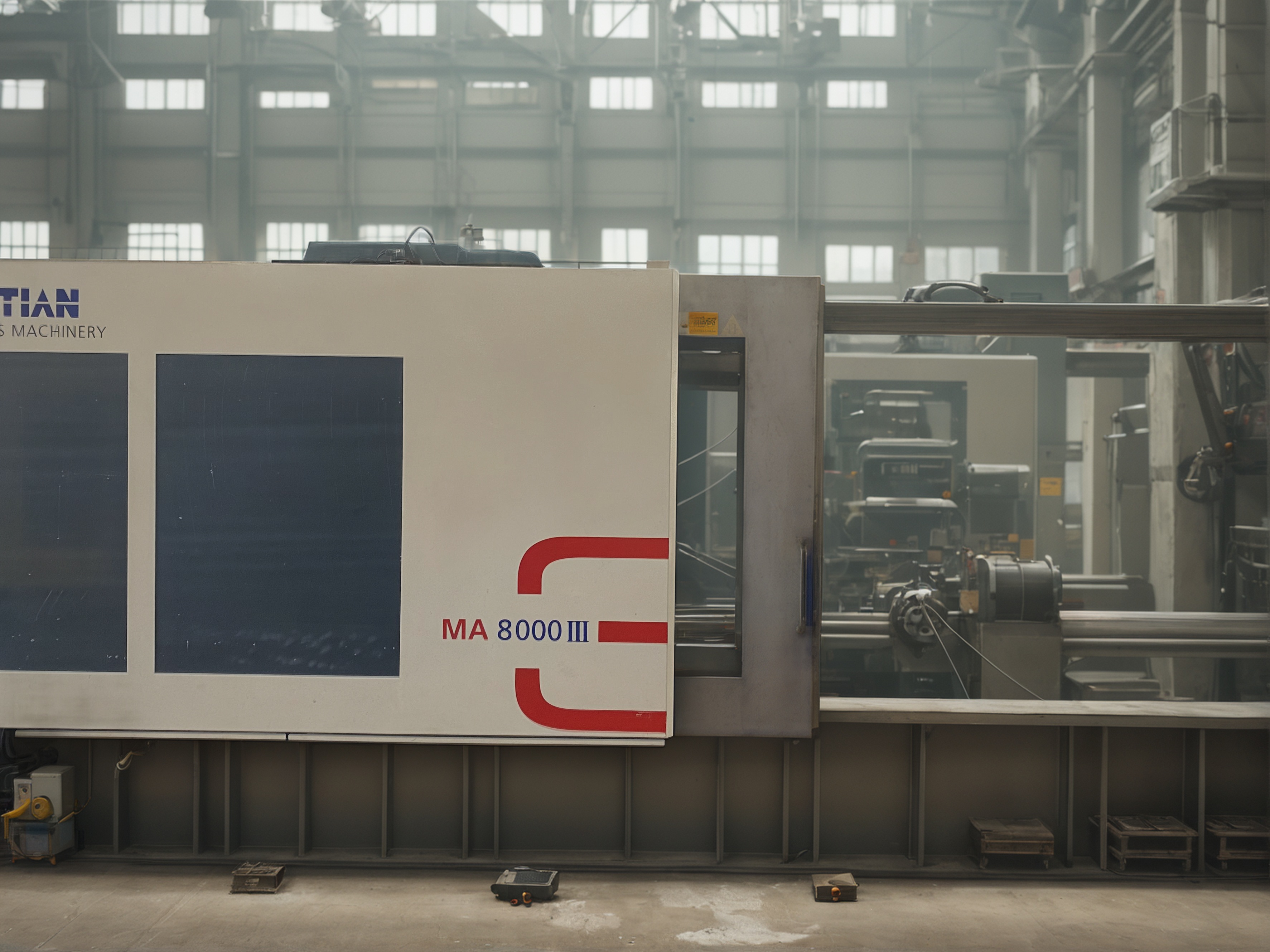

Similarly, the Haitian Mars Series, specifically the Model MA2500 III SE, exemplifies the cutting edge of injection molding technology. This machine perfectly balances power, efficiency, and precision, making it a versatile asset for a wide range of applications. A key feature of the MA2500 III SE is its intelligent servo drive system. This advanced technology offers incredible responsiveness and significant energy savings by consuming power only when needed during the operational cycle. This makes it an economically and environmentally sound choice for manufacturers. With a robust clamping force of 250 tons, it can handle a diverse array of materials and complex mold designs, ensuring that every component produced meets strict quality standards with exceptional integrity. The design of the MA2500 III SE is also thoughtfully compact, allowing for flexible placement in various manufacturing environments where floor space is often at a premium. Inside, high-strength components and a seamlessly integrated mechanism work in perfect harmony to drive productivity to new levels. Advanced control systems provide operators with real-time monitoring and user-friendly interfaces, streamlining operations and maximizing uptime. The machine’s adaptability to different mold sizes underscores its versatility, making it a preferred choice for industries from automotive parts to consumer electronics and medical devices.

When examining these two formidable machines, a clearer picture emerges of what defines a superior modern Conventional Machine. It is no longer just about raw power, but about the intelligent application of that power. The integration of servo systems, advanced controls, and energy-efficient designs has transformed these machines into highly sophisticated manufacturing solutions. They deliver not only on the core promises of reliability and durability but also on the modern imperatives of efficiency, sustainability, and user-centric operation. The precision offered by machines like the Geerpower 1000T3 and Haitian MA2500 III SE is foundational to the quality of countless products we use daily. From the intricate components inside a smartphone to the safety-critical parts in a vehicle, the quality begins with the machine that molds them. This level of performance empowers businesses to innovate, improve product quality, and maintain a competitive edge in a demanding global market.

In conclusion, the evolution of industrial machinery continues to drive progress across the manufacturing landscape. The Geerpower 1000T3 and Haitian MA2500 III SE are more than just pieces of equipment; they are strategic assets that embody the pinnacle of modern engineering. They demonstrate a commitment to value, success, and innovation, providing the reliability needed for today’s production challenges while being engineered for the demands of tomorrow. For any business seeking to enhance its manufacturing capabilities, investing in a high-quality conventional machine is an investment in a future of efficiency, precision, and sustainable growth. The right machine is the cornerstone of a successful production operation, enabling companies to deliver excellence with every cycle.

Description

Additional Information

Privacy Policy

People who viewed this also viewed

Conventional Machine Excellence: MA 1600 III Insights

1. Introduction to Conventional Machine

2. MA 1600 III Injection Molding Innovation

3. Design Excellence and Durability

4. Advanced Technology Integration

5. Optimized User Experience

6. Operational Efficiency Boost

7. Global Support Network

8. Conclusion: Partnering for Success

Conventional Machine: Revolutionizing Plastic Production

1. Introduction to Conventional Machine

2. Structural Integrity and Clamping

3. Injection Unit Mechanism

4. Hydraulic Power System

5. Precision Control Panel

6. Versatility Across Industries

7. Conclusion: Excellence in Manufacturing