In the ever-evolving landscape of modern manufacturing, the Conventional Machine remains a cornerstone of industrial production, providing the power, precision, and reliability that industries depend upon. These workhorses of the factory floor have undergone a remarkable transformation, integrating cutting-edge technology with robust engineering to meet the increasingly complex demands of a global market. Particularly within the plastics industry, advanced injection molding machinery represents the pinnacle of this evolution, offering a seamless blend of high performance, operational efficiency, and cost-effectiveness. The latest generation of these machines is not merely a tool but a comprehensive solution designed to optimize production cycles, minimize waste, and drive sustainable growth for businesses aiming for long-term success.

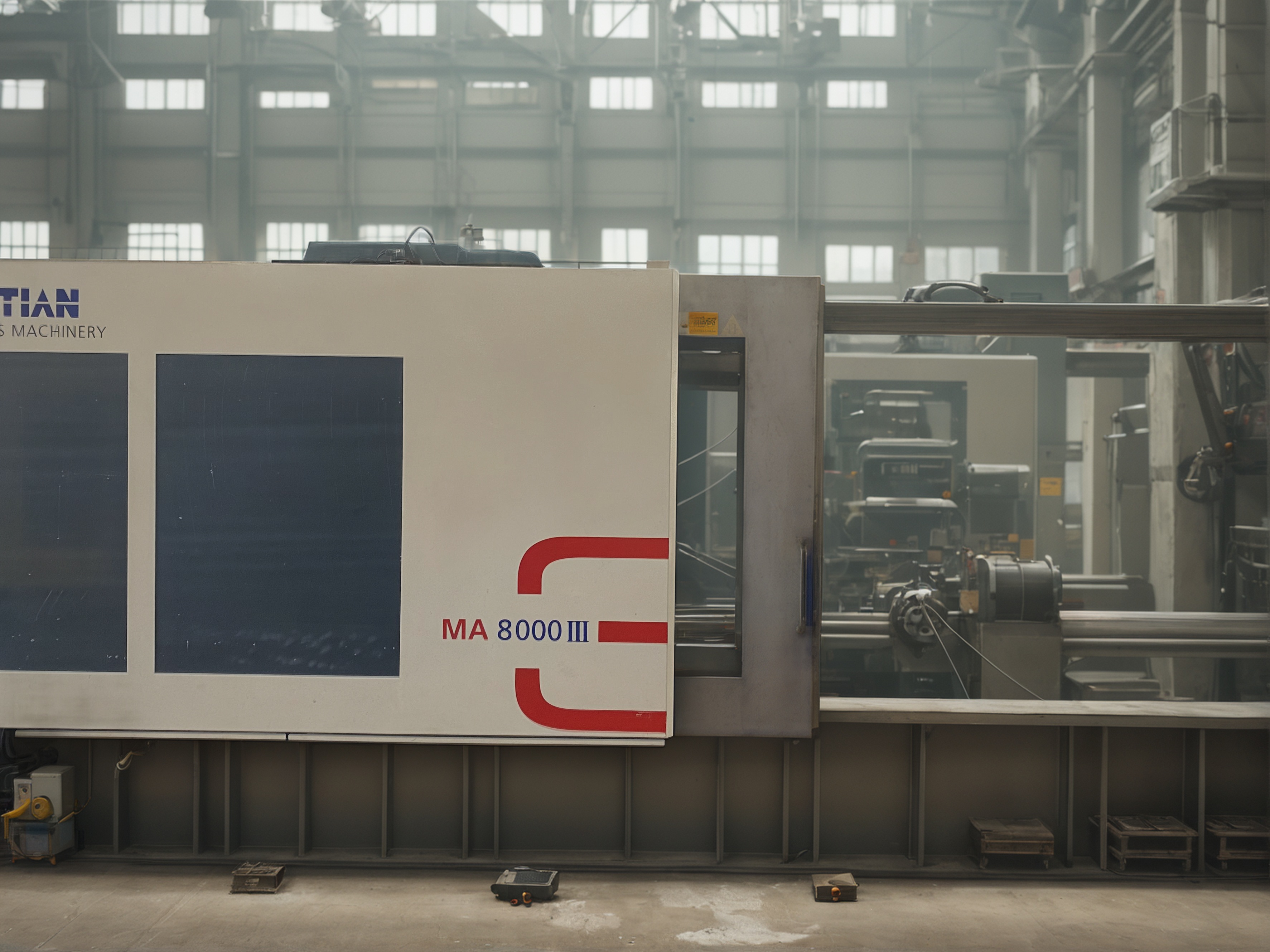

At the heart of a modern industrial machine lies a sophisticated and powerful core, meticulously designed for unparalleled precision and durability. The mechanical design is robust, often featuring a strong, heavy-duty frame built to withstand the rigors of continuous, high-volume production. This solid foundation is critical for ensuring stability during operation, which directly translates to higher quality and consistency in the final product. A key performance metric for injection molding equipment is its clamping force, which can range from a few hundred tons for smaller components to several thousand tons for large-scale parts used in industries like automotive and large appliance manufacturing. This force is applied with incredible precision, ensuring that molds are held together securely during the injection process, preventing defects and ensuring every part meets exact specifications. The synergy between a powerful clamping unit and a high-precision injection system is what allows these machines to transform raw plastic pellets into intricate, flawless components with every cycle.

Technological innovation is most apparent in the advanced control systems that now serve as the brain of the modern Conventional Machine. Gone are the days of complex, purely mechanical controls. Today's machines feature intuitive, user-friendly interfaces with large touch screens and ergonomic control panels. These advanced systems provide operators with complete and granular control over every aspect of the production process, from temperature and pressure to injection speed and cooling time. The ability to save and recall specific mold settings reduces setup times dramatically, optimizing workflow and allowing for quick changeovers between different products. Furthermore, these intelligent controllers offer real-time monitoring and diagnostics, providing valuable data that can be used to maximize productivity, predict maintenance needs, and ensure the entire operation is running at peak efficiency. This level of control empowers manufacturers to reduce training time for new operators while giving seasoned professionals the tools to fine-tune processes for optimal output.

The drive for greater efficiency and sustainability has led to significant advancements in the power systems of industrial machinery. A key innovation is the widespread adoption of high-performance servo motor systems. Unlike traditional hydraulic systems that run continuously, servo motors consume energy only when they are actively performing a task. This intelligent power usage can reduce energy consumption by a substantial margin, leading to significant operational cost savings and a smaller environmental footprint. Beyond energy savings, servo systems offer enhanced responsiveness and precision, allowing for faster and more accurate adjustments to various operational requirements. This results in shorter cycle times, increased output, and improved overall equipment effectiveness. By integrating these energy-efficient technologies, manufacturers are not just improving their bottom line; they are embracing sustainable practices that are becoming increasingly important in today's world.

Versatility is another defining characteristic of the contemporary Conventional Machine. These systems are designed to be highly adaptable, capable of producing a vast array of plastic components for diverse industries. From intricate parts for consumer electronics to robust panels for automobiles and everyday household goods, the same machine can often be configured to handle different materials, mold sizes, and complexity levels. The design of the mold area is a critical factor, with many machines offering spacious platens to accommodate large and complex molds, providing manufacturers with the flexibility to take on a wider range of projects. This adaptability is crucial in a competitive market, as it allows businesses to pivot their production lines to meet changing consumer demands and explore new opportunities without investing in entirely new equipment. The ability to integrate seamlessly with ancillary equipment and industrial automation systems further enhances this flexibility, paving the way for fully automated, smart manufacturing solutions.

Finally, the physical design and long-term reliability of these machines are a testament to top-tier engineering standards. The robust build quality, utilizing durable components, ensures a long operational lifespan and minimizes the risk of unexpected downtime. Thoughtful design extends to maintenance and serviceability, with easily accessible compartments and user-friendly layouts that simplify routine checks and repairs. This focus on durability and ease of maintenance reinforces the machine's value as a long-term investment. When combined with comprehensive technical support and a reliable service network, businesses can operate with confidence, knowing their production capabilities are backed by a machine designed for excellence and a partner committed to their success. Investing in a high-quality machine is more than a capital expenditure; it is a strategic move to secure a competitive edge and build a foundation for future innovation and growth.

Description

Additional Information

Privacy Policy

People who viewed this also viewed

Conventional Machine Excellence: MA 1600 III Insights

1. Introduction to Conventional Machine

2. MA 1600 III Injection Molding Innovation

3. Design Excellence and Durability

4. Advanced Technology Integration

5. Optimized User Experience

6. Operational Efficiency Boost

7. Global Support Network

8. Conclusion: Partnering for Success

Conventional Machine: Revolutionizing Plastic Production

1. Introduction to Conventional Machine

2. Structural Integrity and Clamping

3. Injection Unit Mechanism

4. Hydraulic Power System

5. Precision Control Panel

6. Versatility Across Industries

7. Conclusion: Excellence in Manufacturing